Future Directions in Fuel System Component Digital Twin Technologies

all pannel .com, play99exch win login, gold365:Future Directions in Fuel System Component Digital Twin Technologies

In recent years, digital twin technologies have revolutionized various industries, including manufacturing, healthcare, and transportation. These technologies, which involve creating a digital replica of a physical object or system, have enabled businesses to optimize processes, minimize downtime, and enhance product development. One area where digital twins are making a significant impact is in the fuel system component industry.

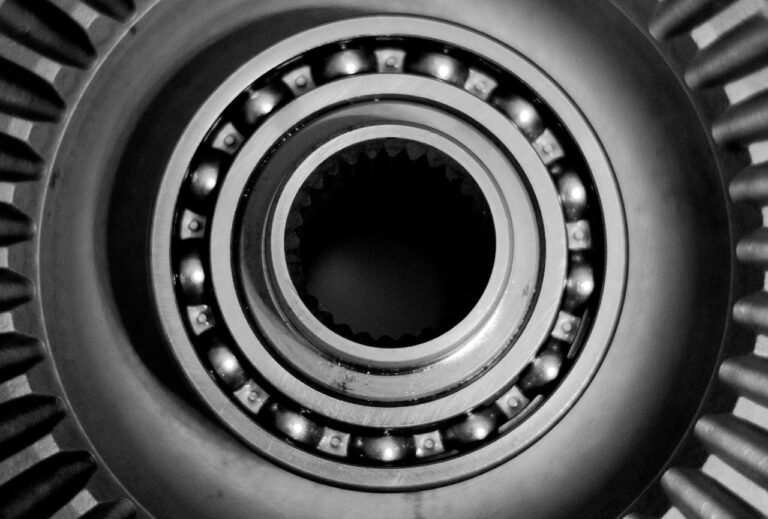

Fuel system components are crucial for the performance of vehicles, machinery, and equipment. The digital twin technology allows manufacturers and operators to monitor, predict, and optimize the behavior of these components in real-time. By combining data analytics, machine learning, and simulation, digital twins can provide valuable insights into the performance, maintenance, and lifespan of fuel system components.

In this article, we will explore the future directions in fuel system component digital twin technologies and how they are shaping the industry.

The Evolution of Fuel System Component Digital Twins

Fuel system component digital twins have come a long way since their inception. Initially, these digital replicas were used primarily for visualization and design purposes. However, with advancements in sensor technology, connectivity, and data analytics, digital twins have evolved into predictive and prescriptive tools.

Today, fuel system component digital twins can capture real-time data from sensors embedded in the components, such as pressure, temperature, flow rate, and vibration. This data is then fed into the digital twin model, which uses algorithms to analyze and predict the performance of the components. By monitoring key metrics and detecting anomalies, operators can take proactive measures to prevent breakdowns and optimize maintenance schedules.

Future Directions in Fuel System Component Digital Twin Technologies

1. Integration of Artificial Intelligence: As artificial intelligence continues to advance, fuel system component digital twins will become more sophisticated in their predictive capabilities. AI algorithms can analyze vast amounts of data and identify patterns and trends that are not immediately apparent to human operators. This will enable more accurate predictions of component failures and optimized maintenance strategies.

2. Internet of Things (IoT) Connectivity: The proliferation of IoT devices is enabling seamless connectivity between fuel system components and digital twin platforms. With IoT sensors embedded in components, operators can gather real-time data on the performance of each part of the system. This data can then be used to update and refine the digital twin model continuously, leading to more accurate predictions and insights.

3. Augmented Reality (AR) and Virtual Reality (VR) Integration: AR and VR technologies are being integrated into fuel system component digital twins to provide immersive, interactive experiences for operators. By overlaying digital twin data onto the physical environment through AR glasses or VR headsets, operators can visualize component performance in real-time and make informed decisions on maintenance and troubleshooting.

4. Edge Computing: Edge computing technologies are being deployed to process data closer to its source, reducing latency and enabling real-time analytics. By implementing edge computing in fuel system component digital twins, operators can capture, analyze, and act on data instantaneously, without relying on cloud-based solutions. This will be particularly beneficial for applications requiring quick response times, such as predictive maintenance.

5. Blockchain Technologies: Blockchain technologies are being explored to enhance the security and transparency of fuel system component digital twins. By storing data in a decentralized, tamper-proof ledger, operators can ensure the integrity of the information being used to model and analyze component performance. This will be critical for industries where data accuracy and security are paramount.

6. Collaborative Digital Twin Ecosystems: The future of fuel system component digital twins lies in creating collaborative ecosystems where manufacturers, operators, and service providers can share data and insights. By pooling resources and expertise, stakeholders can collectively improve the accuracy and effectiveness of digital twin models, leading to better outcomes for all.

7. Sustainability and Environmental Impact: With growing concerns about climate change and environmental sustainability, fuel system component digital twins will play a crucial role in optimizing energy usage and reducing emissions. By monitoring and analyzing energy consumption, operators can identify opportunities to increase efficiency and minimize environmental impact, aligning with global sustainability goals.

FAQs

Q: What are the benefits of fuel system component digital twins?

A: Fuel system component digital twins offer numerous benefits, including predictive maintenance, optimized performance, reduced downtime, and improved efficiency. By monitoring and analyzing component behavior in real-time, operators can proactively address issues before they escalate, leading to cost savings and enhanced reliability.

Q: How do fuel system component digital twins differ from traditional maintenance strategies?

A: Traditional maintenance strategies are often reactive, relying on scheduled inspections and repairs. In contrast, fuel system component digital twins enable predictive and prescriptive maintenance, leveraging real-time data and analytics to anticipate issues and optimize maintenance schedules. This proactive approach minimizes downtime and maximizes the lifespan of components.

Q: How can companies implement fuel system component digital twins?

A: Companies looking to implement fuel system component digital twins should start by assessing their current infrastructure, data capabilities, and technology readiness. Collaborating with experts in digital twin technologies and IoT connectivity is essential to developing a robust digital twin platform tailored to specific needs and goals.

Q: What are the key challenges in adopting fuel system component digital twins?

A: Some of the key challenges in adopting fuel system component digital twins include data integration, cybersecurity risks, interoperability issues, and technology scalability. Companies must address these challenges by investing in robust data management systems, cybersecurity measures, and scalable solutions to ensure the success of their digital twin initiatives.

In conclusion, fuel system component digital twin technologies are rapidly advancing, offering unprecedented opportunities for manufacturers, operators, and service providers to optimize performance, reduce downtime, and enhance sustainability. By embracing the future directions in digital twin technologies outlined in this article, stakeholders can harness the power of data, analytics, and connectivity to transform their operations and drive innovation in the fuel system component industry.