Sustainability Practices in Fuel Injector Energy-Efficient Manufacturing Processes

betbhai9, playexch in login, lotus365 in login password:Sustainability is a key focus in the manufacturing industry, with companies striving to reduce their environmental impact while still meeting the high demands of consumers. One area where sustainability practices are gaining traction is in fuel injector energy-efficient manufacturing processes.

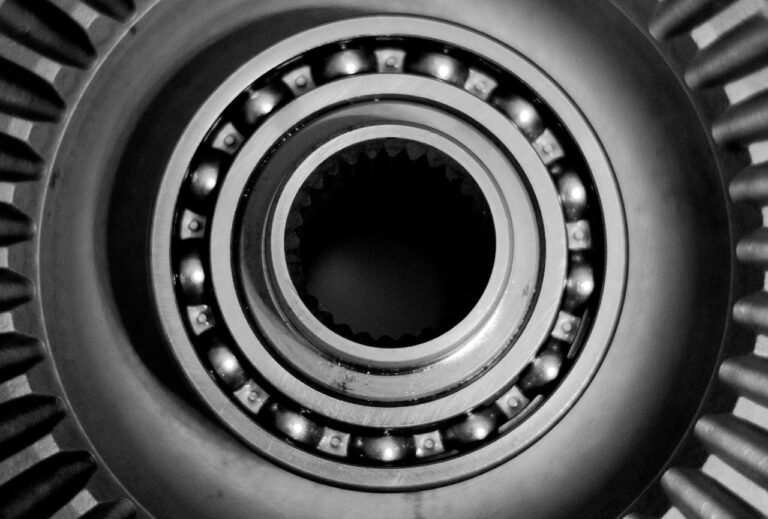

Fuel injectors play a crucial role in the combustion process of engines, delivering fuel to the engine cylinders for optimal performance. However, the traditional manufacturing processes used to produce fuel injectors can be energy-intensive and have a significant carbon footprint. As a result, many companies are turning to sustainable practices to reduce their environmental impact while still delivering high-quality products.

In recent years, fuel injector manufacturers have started implementing energy-efficient manufacturing processes to reduce their energy consumption and greenhouse gas emissions. These sustainable practices not only help companies meet their environmental goals but also contribute to cost savings and improved efficiency. Here are some of the key sustainability practices being implemented in fuel injector manufacturing processes:

1. Energy-Efficient Machinery: Companies are investing in energy-efficient machinery that consumes less power and produces fewer emissions. By using state-of-the-art equipment, manufacturers can reduce their energy consumption and lower their carbon footprint.

2. Renewable Energy Sources: Many fuel injector manufacturers are turning to renewable energy sources such as solar and wind power to meet their energy needs. By utilizing clean energy sources, companies can further reduce their environmental impact and promote sustainability.

3. Lean Manufacturing Practices: Lean manufacturing practices focus on minimizing waste and optimizing efficiency in production processes. By implementing lean principles, companies can reduce energy consumption, improve productivity, and reduce their overall environmental impact.

4. Recycling and Waste Reduction: Fuel injector manufacturers are implementing recycling programs and waste reduction initiatives to minimize their environmental footprint. By recycling materials and reducing waste, companies can conserve resources and promote sustainability.

5. Green Supply Chain Management: Companies are working with suppliers who adhere to sustainable practices and environmental standards. By incorporating green supply chain management principles, manufacturers can ensure that the entire production process is environmentally friendly.

6. Employee Training and Engagement: Fuel injector manufacturers are educating their employees on sustainability practices and encouraging them to actively participate in green initiatives. By engaging employees in sustainability efforts, companies can create a culture of environmental responsibility and promote long-term sustainability.

By incorporating these sustainability practices into fuel injector manufacturing processes, companies can reduce their environmental impact, lower their energy consumption, and promote a more sustainable future. These green initiatives not only benefit the environment but also contribute to cost savings, improved efficiency, and enhanced brand reputation.

FAQs

1. How do energy-efficient manufacturing processes benefit fuel injector manufacturers?

Energy-efficient manufacturing processes help fuel injector manufacturers reduce their energy consumption, lower their carbon footprint, and promote sustainability. These practices also contribute to cost savings, improved efficiency, and enhanced brand reputation.

2. What are some examples of renewable energy sources used in fuel injector manufacturing?

Some examples of renewable energy sources used in fuel injector manufacturing include solar power, wind power, and geothermal energy. By utilizing clean energy sources, companies can reduce their environmental impact and promote sustainability.

3. How can employees contribute to sustainability practices in fuel injector manufacturing?

Employees can contribute to sustainability practices in fuel injector manufacturing by actively participating in green initiatives, conserving resources, and promoting environmental responsibility. By engaging employees in sustainability efforts, companies can create a culture of environmental stewardship and promote long-term sustainability.