Insights into the Manufacturing of Fuel System Fuel Composition Sensors

betbhai com, playexch login, gold 365:Manufacturing fuel system fuel composition sensors is a critical process that requires precision and attention to detail. These sensors play a vital role in the proper functioning of an automobile’s fuel system, providing valuable information about the composition of the fuel being used. In this article, we will delve into the insights behind the manufacturing of fuel composition sensors and the technology behind them.

Understanding Fuel Composition Sensors

Fuel composition sensors are electronic devices that monitor the composition of the fuel being used in a vehicle. They can detect the presence of alcohol, water, and other contaminants in the fuel, providing valuable data to the vehicle’s engine control unit. This information allows the engine to adjust its performance to maximize fuel efficiency and reduce emissions.

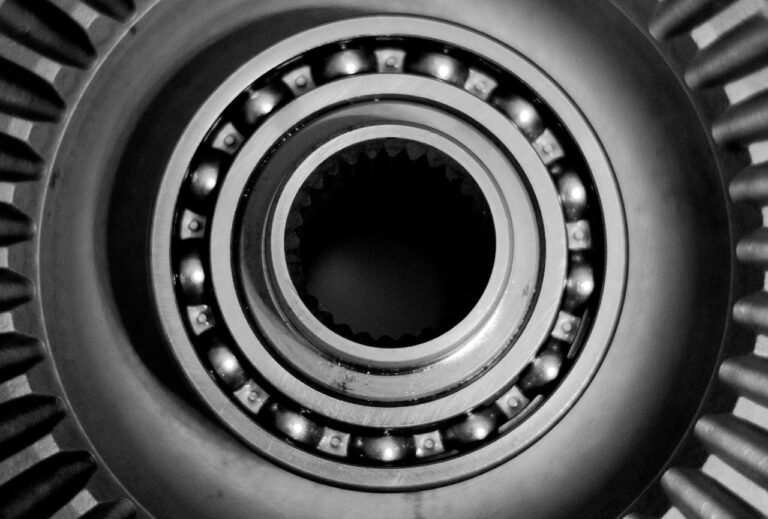

The manufacturing process of fuel composition sensors begins with the selection of high-quality materials. The sensor is typically made up of a sensor element, which detects the fuel composition, and a housing that protects the sensor element from external factors. The sensor element is usually made of materials such as platinum or palladium, which are known for their excellent conductivity and sensitivity to changes in fuel composition.

Once the materials are chosen, the sensor element is fabricated using advanced manufacturing techniques such as thin-film deposition and photolithography. These processes ensure that the sensor element is precise and reliable, capable of providing accurate readings in various operating conditions.

After the sensor element is fabricated, it is integrated into the housing, which is designed to withstand the harsh conditions inside a vehicle’s fuel system. The housing is typically made of materials such as stainless steel or plastic, which are resistant to corrosion and temperature variations.

To ensure the accuracy of the sensor, it undergoes rigorous testing during the manufacturing process. This includes calibration tests to verify its sensitivity to different fuel compositions and environmental conditions. The sensor is also subjected to vibration and thermal cycling tests to ensure its durability and reliability in real-world conditions.

Overall, the manufacturing process of fuel composition sensors is a complex and intricate process that requires specialized knowledge and expertise. By using high-quality materials and advanced manufacturing techniques, manufacturers can produce sensors that are reliable, accurate, and efficient in monitoring fuel composition.

Key Insights into Manufacturing Fuel Composition Sensors

1. Material Selection: The choice of materials is crucial in the manufacturing of fuel composition sensors. High-quality materials such as platinum and stainless steel are used to ensure the sensor’s accuracy and durability.

2. Advanced Manufacturing Techniques: Thin-film deposition and photolithography are advanced manufacturing techniques used to fabricate the sensor element with precision and reliability.

3. Housing Design: The design of the housing is important to protect the sensor element from external factors and ensure its longevity in the harsh conditions of a vehicle’s fuel system.

4. Calibration and Testing: Calibration tests are essential to verify the sensor’s sensitivity and accuracy in detecting fuel composition. Rigorous testing, including vibration and thermal cycling tests, ensure the sensor’s durability and reliability.

5. Quality Control: Quality control measures are implemented throughout the manufacturing process to maintain the high standards of the fuel composition sensor. This includes inspections and checks at each stage of production.

6. Innovation and Research: Continuous research and innovation are key to improving fuel composition sensor technology. Manufacturers invest in research and development to stay ahead of the curve and offer the latest advancements in sensor technology.

FAQs

Q: How do fuel composition sensors work?

A: Fuel composition sensors work by detecting the presence of alcohol, water, and other contaminants in the fuel. They provide this information to the vehicle’s engine control unit, which uses it to adjust the engine’s performance for optimal fuel efficiency.

Q: Are fuel composition sensors necessary for all vehicles?

A: While not all vehicles are equipped with fuel composition sensors, they are becoming increasingly common in newer vehicles. These sensors play a crucial role in optimizing fuel efficiency and reducing emissions, making them a valuable addition to modern vehicles.

Q: Can fuel composition sensors be repaired if they malfunction?

A: In most cases, fuel composition sensors cannot be repaired and must be replaced if they malfunction. It is important to have a qualified technician diagnose any issues with the sensor and replace it with a new one if necessary.

Q: How long do fuel composition sensors last?

A: Fuel composition sensors are designed to last for the life of the vehicle, but their lifespan can vary depending on factors such as driving conditions and maintenance. Regular maintenance and inspections can help ensure the longevity of the sensor.

Q: Are fuel composition sensors expensive to manufacture?

A: The cost of manufacturing fuel composition sensors can vary depending on factors such as materials used, manufacturing techniques, and quality control measures. While the initial cost of production may be high, the benefits of using high-quality sensors often outweigh the cost.

In conclusion, the manufacturing of fuel composition sensors is a complex and intricate process that requires precision, advanced technology, and quality control measures. By using high-quality materials, innovative manufacturing techniques, and rigorous testing, manufacturers can produce sensors that are reliable, accurate, and efficient in monitoring fuel composition. These sensors are essential components of modern vehicles, helping to optimize fuel efficiency, reduce emissions, and improve overall performance.